FOUR STAGE, FLUIDIZED BED GASIFICATION PROCESS MINIMIZES NOX

F. Michael Lewis, Roger T. Haug, Environmental Engineering Division, Bureau of Engineering, City of Los Angeles

ASME Paper No. FBC99-0205, 15th International Conference on Fluidized Bed Combustion, Savannah, Georgia, May 16 - 19, 1999

Select image and "Original" to enlarge.

BACKGROUND AND INTRODUCTION

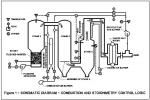

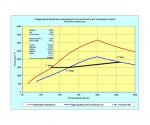

In 1981, after a long and thorough study of alternative methods of sewage sludge (biosolids) disposal, the City of Los Angeles (CLA) embarked on a pilot test program to incinerate dried sewage sludge from its Hyperion Wastewater Treatment Plant. This dried sludge is typically 47% ash, 53% combustible, and has an average higher heating value (HHV), moisture, ash-free (MAF) of 10,675 Btu/Lbm. The dried sludge is called sludge derived fuel (SDF). Approximately 8% of the MAF fraction of SDF is fuel-bound nitrogen. When SDF, with its extremely high fuel-bound nitrogen, was combusted in conventional multiple hearth and fluidized bed pilot plant furnaces, NOX emissions were extremely high (>1,000 ppm). Faced with this dilemma, the CLA initiated an R&D program to reduce NOX. The final result of this effort was the development of three (3) full-size, fluid bed gasifiers (two operational - one standby) that operated in a staged combustion mode. These furnaces were operated by CLA from 1986 to 1996.

This was a FOUR stage gasification process. A THREE stage gasification is illustrated below.

See attachment.

F. Michael Lewis

fml@earthlink.net